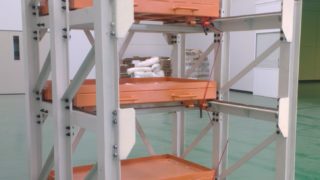

Selective Rack

Selective Rack is the most standard type of rack to store pallet loads.

If you don’t have any types of rack systems to store your pallet loads, try the selective rack at first.

It will help you visualize your warehouse easily so that you can get easy inventory management such as the location control, and FIFO control.

Basics of Selective Rack

- Selective rack is the most low cost storage system compared to the other type of storage systems.

- Selective rack is the easiest way for the inventory control, location control and FIFO control.

- Selectivee rack is available for any type of industries.

- Selective rack is mainly for the pallet load. But, you can use it to store plastic boxes or other no-palletized loads with some additional parts for selective rack.

- The available maximum load weight for 1 pallet load is around 1ton. (It depends on the load size.)

- You can change the beam position up or down according to the height of your load height. (The widhth of the rack is not adjustable. )

- You can change the location of the installed rack easily. You can remove the selective rack easily too.

Disadvantages of Selective Rack

You need an aisle width big enough according to the type forklift you have. (90degree stacking aisle) You need around 3m for the aisle width by the stand-on reach fork lift truck. And you need around 4m for the aisle width by the sit-on counter balance truck.

And, in many cases, the space for the forklift aisle is bigger than the space for the selective rack. So we strngly recommend you to chose the selective rack as high as possible. For example, if you have a plan of 100pallets storage rack by total 4 stacks. Try to think about 5th stack, and then you can get additioanl 25 pallets capacity.

Installation Record

For Warehouse

Pallet Rack

For Plastic Injection Factory

Selective Rack to store materials for the plastic injection.

For the Storage of Molds and Dies

Selective Rack to store molds and dies with special wooden palets.

For the Storage of Molds and Dies with PVC curtain

Selective Rack to for molds and dies with PVC curtain to protect dusts.

For Slitting Factory

Selective Rack for slitting factory.